Enhanced TDS

Identification & Functionality

- Chemical Family

- Chemical Name

- Manufactured By

- CASE Ingredients Functions

- Fluids & Lubricants Functions

- Plastics & Elastomers Functions

- Technologies

- Product Families

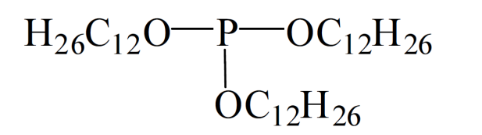

- Chemical Structure

Trilauryl Phosphite

Features & Benefits

- CASE Ingredients Features

- Materials Features

- Advantages

Protect polymer against thermo-oxidative degradation during manufacture and processing. Increase the service life time heat resistance of finished articles.

Applications & Uses

- Compatible Polymers & Resins

- Coating End Applications

- Plastics & Elastomers End Uses

- Use Level

- 0.05 - 1.0%

- Recommendation

EVERAOX 201 is particularly recommended for polyurethane, PVC, polyester fibers and polypropylene, solvent-based coatings, elastomers, adhesives& sealants, and other organic substrates. Typically dosage range of EVERAOX 201 is 0.05 - 1.0 % by weight and provides long term thermal stability to the polymer.

Properties

- Appearance

- Clear liquid

- Physical Properties

Value Units Test Method / Conditions Specific Gravity (at 25°C) approx. 0.866 - 0.881 - - - Typical Properties

Value Units Test Method / Conditions Molecular Weight 586 g/mol - - SDS Physical and Chemical Properties

Value Units Test Method / Conditions Color Clear - - Density (at 25°C) 0.866 - 0.881 g/cc - Flash Point min. 90 °C - Odor Odorless - - Physical Form Liquid - - Soluble in Water (<0.1%, at 20°C) - - Vapor Pressure (at 150°C) 7 hPa -

Regulatory & Compliance

- Chemical Inventories

Safety & Health

- Handling & Safety

Personal equipment for protection is recommended. Excess exposure to the product should be avoided. Wash thoroughly after handling.

Packaging & Availability

Storage & Handling

- Storage Conditions

EVERAOX 201 should be kept in a dry, dark place without any light exposure.